If you are stuck under home quarantine like us, perhaps now is a good time to refurbish your vintage Revere Ware. Here are some tips.

New Parts

We’ve got you covered there.

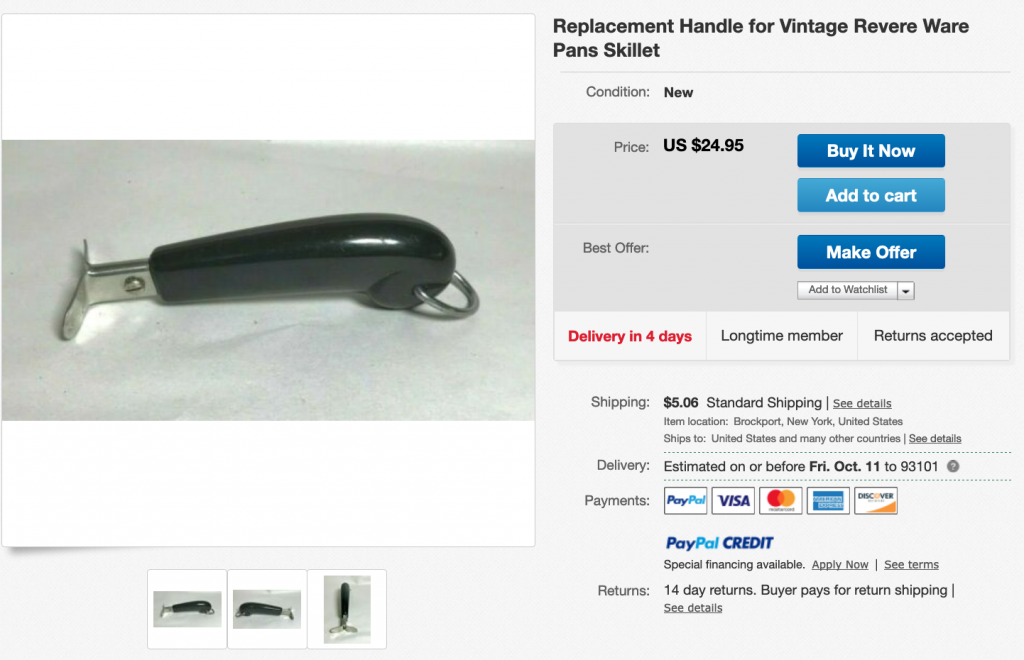

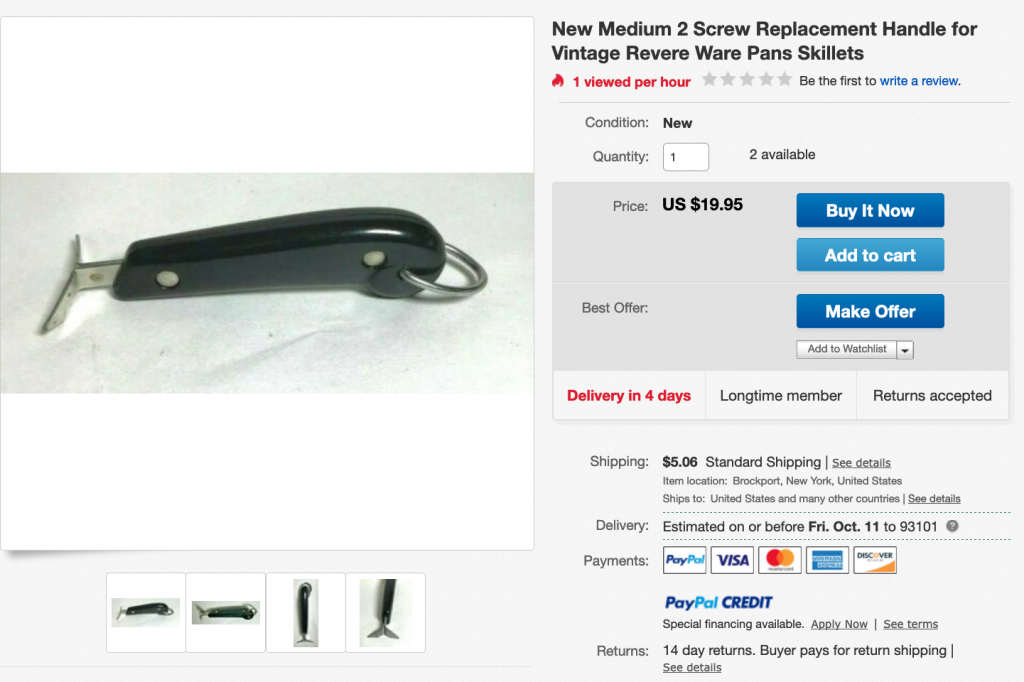

For your vintage skillets and sauce pans that have handles with two screws through the Bakelite part we carry handles and hardware, and lid knobs. And here is our sizing sheet that helps you find the right size.

For your post-1968 skillets and sauce pans that have handles with a single screw through the metal part, we carry handles and hardware, and lid knobs. And here is our sizing sheet that helps you find the right size.

For your pots and Dutch ovens, we carry handles and lid knobs.

For your vintage 4 quart, and model 1574 and 1576 pressure cookers, we carry gaskets.

For your percolators, we carry replacement glass tops.

For your 2 1/3 quart kettles, we carry handles, triggers, and caps. Not sure what size your kettle is? Use our kettle identifier.

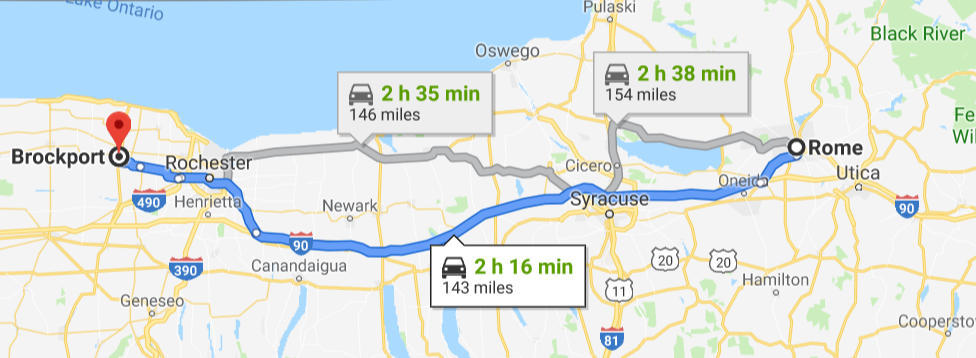

Our fulfillment warehouse and our Amazon.com stock are both complete right now and will be for the duration.

Cleaning

Here is our handy cleaning guide. That will help you get years of gunk off and polish it to a shine.

Quick summary:

For burnt on gunk on the inside of a pan, use automatic powdered dishwasher detergent and vinegar, and bring it to a boil. Then scrap off the gunk with a flat metal spatula.

For gunk on the outside, submerge the entire piece into a large pot with a lot of baking soda in it and bring to a boil. Then work off the gunk with repeated scraping and scrubbing and immersion in the boiling baking soda mixture.

To clean the inside of a cookware piece well, use a green Scotch Brite pad.

To clean the outside of a piece to a nice shine, use Bar Keepers Friend.

Repairs

Have a nub instead of a screw on your lid? Here is our guide for that.

Did your lid knob screw come off? Here is our guide for that.

Information

Want to learn more about the history of Revere Ware? Now is a good time to read up with our basic history of Revere Ware Cookware, our detailed history of the Revere company, or our photo guide to Revere Ware products.

Enjoy!