A customer wrote us with the following question:

Can my 62 year old Revere Ware “pasta-pot” be copper re-coated ? I had boiled water dry.

The short answer is no, not that we know of. We have never heard of a service (or a process) that does this. There is something somewhat similar for copper cookware, called re-tinning, but that is a very different process and doesn’t apply here.

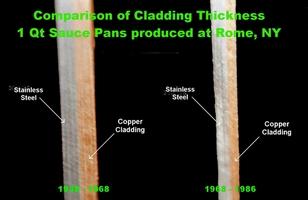

We have done tests specifically where we heated a dry pan to see what would happen. And indeed, some of the copper came off. However, the older, well-made cookware (and 62 years old fits squarely in that category) has a pretty thick copper layer:

In our experiment, the amount of copper that came off was minimal given the overall thickness of the layer.

Having said that, if you are seeing stainless steel through the copper layer, I would thank your pan for many years of good service, and find yourself a vintage replacement. You can find a robust market for used Revere Ware cookware on eBay, and using our helper site, can likely find a replacement for just about anything.

Base material can be repaired. It takes someone who knows about “Metallurgy”.

The item must be heated in an oven, within -20′ of melt*, Than the “same composite”, or close to the type of material should be brought to -10′ of melt*. Flux! Flux! This you MUST! Upon touching…the Hotter surface draws the Soddier into it’s cavity. Slowly cool, Some people say…cold quench…I don’t agree…harder to repair. Just cool and you have a hundred year repair

I dropped my D 96-C Paul Revere tea kettle and the copper clad bottom now has a small leak on the seam attached to the main body of the kettle so I cannot boil water in it. Can this kettle be repaired? I shall look forward to your response.

It is possible a machine shop could braze it so that it no longer leaked. However these are plentiful on eBay; I would just purchase a new used one.

https://www.revereware.org/tea.html

How thick is the copper on pre 1968 cladding?

I just measured a vintage and a newer era 10″ skillet with a set of calipers. Not hugely accurate, but I get 1.1mm for the vintage bottom and .8mm for the newer era one.

so you know anyone who will do this for me to save on landfill (adhere copper base back onto a stainless steel saucepan)?

I have never heard of anyone doing this type of repair.

Yes, it can be repaired. You’ll need to find someone that does electroplating.

They will have the setup for this, and it is easy to do. They will have the

equipment, but this is what they will do. A plastic tub, with your pot ( with a weight inside

to counter the buoyancy ) up to the copper line with a solution of copper sulfate, a negative

electrode clipped to your pot lip, and a positive electrode clipped to a piece of copper pipe

sitting in the solution. The electrodes connected to a dc power source. When turned on

the copper from the solution will plate out on the pot bottom, the copper from the pipe will

keep the solution saturated with copper while plating. If left for a couple of days, you will have

considerable copper deposited securely to your pot bottom. you could save money, if you get

your kids to do it. Kids love to electroplate. You could buy the equipment and they could do it.

I’m sure they know what equipment they would need. Adults just don’t think of these things.

Yes, I’m a scientist ( chemist ) but this is easy to do, and an absolute fix.

Would love a video if you know of one, or want to make one.